Emergency Power

- Home

- Solutions

- MEP Solutions

- Emergency Power

Emergency Power Systems are a backup form of electrical supply that is typically critical to maintain and ensure the primary electrical power needed by an infrastructure during an emergency is delivered. Such a system is usually on standby and is operated and activated automatically when a power cut or a blackout occurs. It’s a complementary addition to any business or workplace that guarantees minimal downtime and operational efficiency.

Emergency Systems typically have a set standard format, including a fossil-fueled engine (diesel or petrol) that turns a generator to supply demand of power or electricity to the building. Many configurations and a specific design or type may exist to meet a specific demand such as a particular voltage rating (400V) to supply certain systems.

Emergency Power System usually can be a group of many sub-systems or different components that serve a specific role depending on the power requirements of different facilities. For example, a low voltage, a high current system such as those found in lighting equipment may need a high-end generator and control system to meet its requirement, while a simple emergency lighting (lower luminosity) may run on batteries.

Optimization of an Emergency Power System around a set of predetermined requirements ensures effective operations at all times. The designer usually considers a broad range of parameters before the decision is made on what is essential.

This may include;

- Overall Power Requirement.

- Frequency of Blackouts or Feed Power Instability.

- Critical Components (I.e., Security Systems should not fail).

- Geographical location of the site.

- Safety Requirements.

- Total time of emergency backup expected to be needed.

- Size and Space needed.

- System Components and Various Storage Technologies

To create a decent and working emergency backup a set of components need to be selected. Components may include;

- System Cabling Runs.

- Sensors.

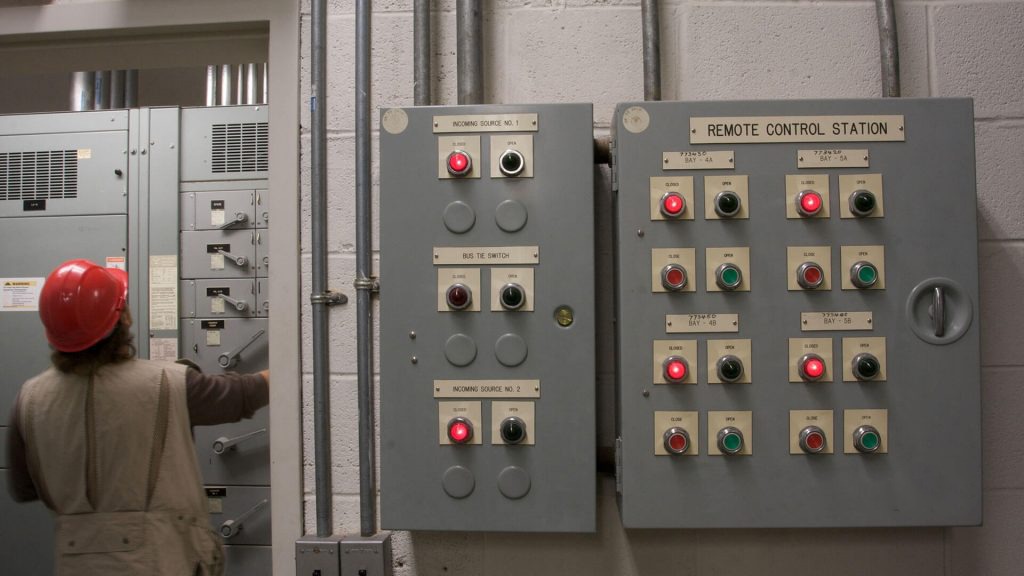

- Electrical Switchboards and Panels.

- A Power Generative Unit (Diesel Engine etc.).

- Generator.

- Fuel Tank and Electrical Storage (Batteries, Flywheels etc.).

- Selection of storage and their types are based on; Duration of Power outage.

- Duration of Power outage.

- Expected Power needed.

- Efficiency of storage.

Many Storage systems can be used and these include;

- Lithium-Ion Batteries.

- Mechanical Flywheels.

- Thermal Storage (Energy Recovery Systems (ERS), Captured thermal energy from Air Vents and so on, etc.).

- Compressed Air.

- Hydroelectric conversion.

- The most common are Lithium-Ion batteries, yet their effective capacity is lower than most and they also require safe storage space.

- Mechanical Flywheels are efficient yet their initial cost is quite high. They are hardly justifiable for small power requirements and maintenance is usually costly and challenging.

- Thermal Storage and Hydroelectric Systems require large spaces which might not be available.

- Compressed Air systems are space-efficient but store the lowest energy of them all.

When Emergency power systems are needed, their power supply instantly replaces the main feed power during an EPO (Emergency Power Off or Shutdown) and continually provides power or electricity to the facility. This is done by conversion of mechanical power or movement to electrical power via a rotating shaft.

This rotating shaft is connected to a generator, which has the required stator that, by the help of the produced magnetic field, causes current to flow. This current is stabilized and controlled to a required AC or DC supply with the correct voltage to be used.

Emergency Power Systems Maintenance

Emergency power systems are usually in good condition and require low maintenance intervals as they’re scarcely used. The System may require regular checkups and evaluation of its status, but actual maintenance costs and fixes are rare. Initially, Installation may require an environmental licensing, certification and safety checks to be passed that meet international and industries’ standards to ensure system compliance before starting the project.

If a fix or a service is required, it’s usually costly and requires an almost complete overhaul as it’s classified as unreliable and of low quality. The cost is usually skewed to the labour of trained professionals required to plan and work on the system.