Chilled Water System

- Home

- Solutions

- MEP Solutions

- Chilled Water System

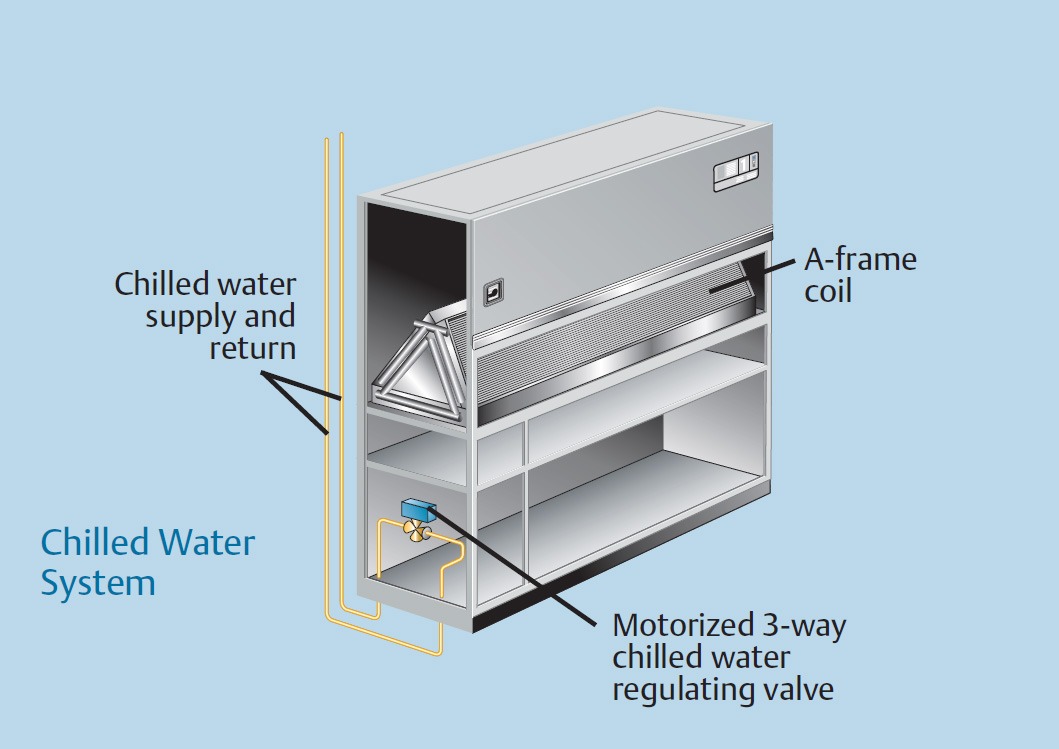

The chilled water system is an HVAC system that uses hot or cold water to adjust air temperature, instead of the regular refrigerant – freon. Which eliminates the need for a condensing unit which contains the condenser, compressor and expansion valve.

The system uses water temperature for cooling and heating the area, which is pumped to the central cooling system (evaporator) through isolated ducts.

It transfers heat from the inside air to cold water circulating through chilled water loops, the water then returns to the chiller where refrigerant recools the water, this is called the refrigeration cycle.

Pipes are used in the chilled water loops to circulate water from the chiller around the building walls, through air conditioning units such as air handling units (AHUs) and fan coil units (FCUs). Where the chilled water goes through a heat exchanging coil to reduce its temperature. The cooled air from the coil is then blown to the area, then the water circulates back to the chiller to start the process all over.

Best places to use the chilled water system

The chilled water system is commonly used in medium and large-sized buildings that require large cooling capabilities such as:

- Hypermarkets

- Industrial processes

- Commercial air conditioning such as offices and factories

Chilled water system types

Chilled water systems are available in two forms; a simple form that comes with a single chiller and a pump, and a more complex form that comes with multiple chillers, pumps, cooling towers, heat exchangers and valves.

These two forms are available in two main types:

Air-cooled chillers

This kind is installed outside the building, which helps in exhausting heat from chilled water to the outside air when refrigerant passes through the condenser coil.

The refrigerant then circulates to the expansion valve to be cooled and back to the evaporator to cool the chilled water.

Water-cooled chillers

This kind is installed inside the building. Unlike the air-cooled chillers, this system exhausts heat from chilled water to an isolated waterline known as the condenser water line.

The condenser water picks up the heat when it goes through the chiller, then returns to the cooling tower, which is located outside of the building, so heat is removed from the condenser water by evaporating some of it to the atmosphere. The cool condenser water flows back to the chiller, and the operation is repeated all over again.

Chilled water system Benefits

- Chilled water systems are a centralized cooling system that can help in cooling and air distribution in medium and large buildings or even multiple buildings.

- The system equipment is located in one place (inside or outside the house), which helps ease the maintaining process.

- Energy-efficient, as the system saves energy in the long run in comparison to smaller systems.

- Cost-effective especially in large and multiple buildings arrangements.

- The system is customizable according to the area and the efficiency needs of the users, as different compressors, refrigerants and accessories can be installed.

Alternatives in the market

- Direct Expansion (DX)

- Split-System air conditioners

- Concealed ducted split

- Variable refrigerant flow (VRF)

- Variable refrigerant volume (VRV)

Maintenance

Chilled water systems will operate more efficiently with constant maintenance.

Cleaning and maintaining condenser coils, refrigerant charge and Condenser water loops can help in extending the system life span.