2 Variable Refrigerant Systems (VRF and VRV)

- Home

- Solutions

- MEP Solutions

- 2 Variable Refrigerant Systems (VRF and VRV)

Variable Refrigerant Flow (VRF)

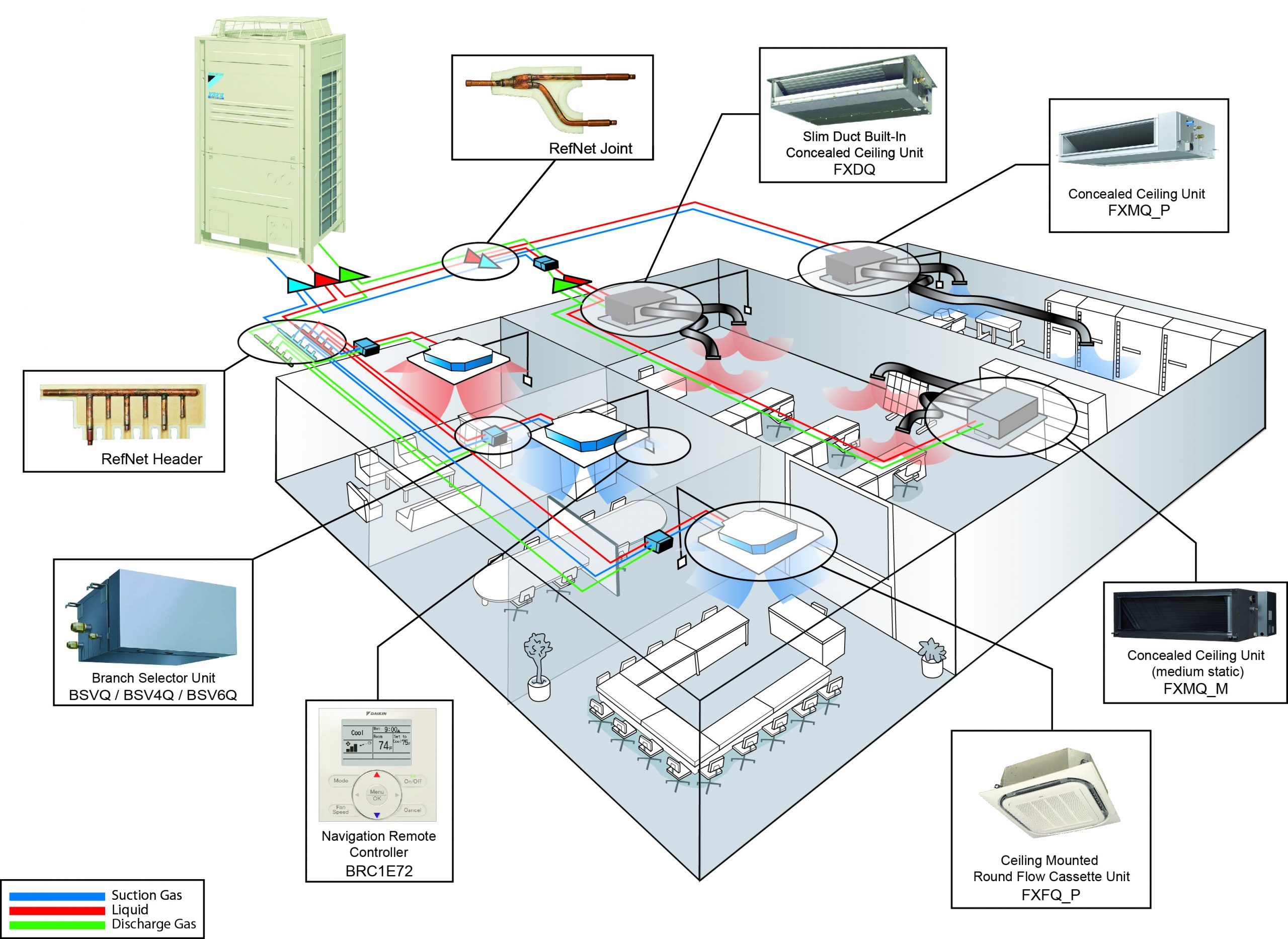

A variable refrigerant flow system utilizes a configuration in which multiple indoor units (evaporators) are used with a single outdoor unit (condenser) to enable multiple zone air conditioning while keeping the cost at a minimum.

The term variable refrigerant flow refers to the power of the system to regulate the quantity of refrigerant flowing to the multiple evaporators. The utilization of multiple indoor units allows a variable cooling capacity rating for each unit depends on the room or zones’ space.

Variable Refrigerant Flow (VRF) Types

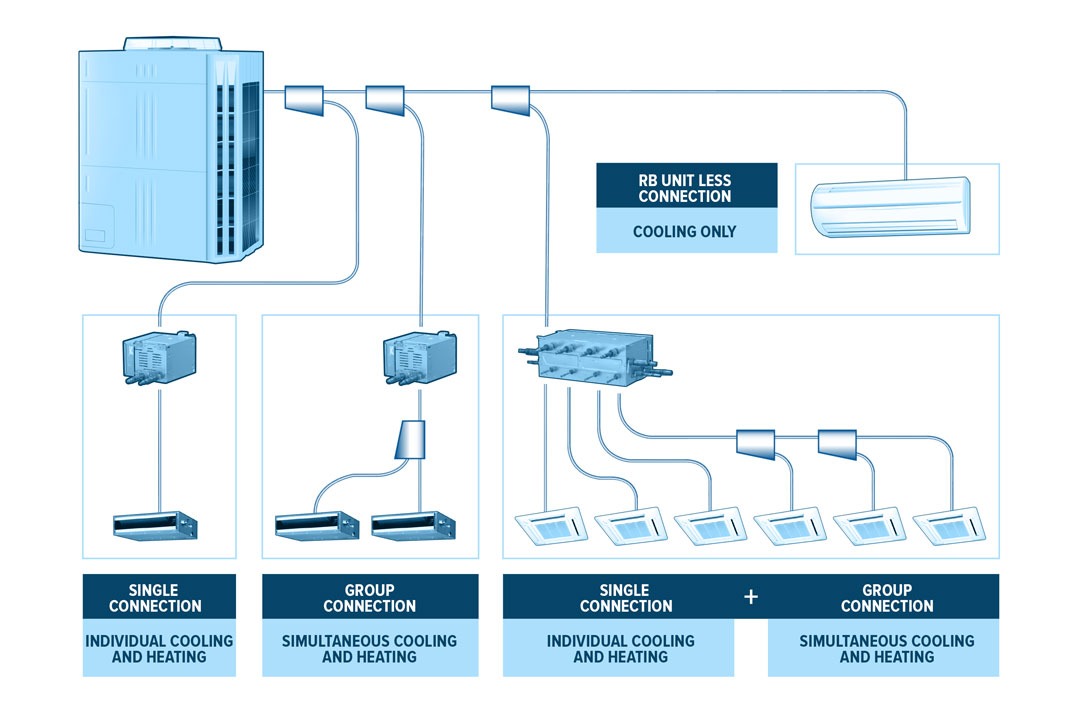

Various types of VRF are available to choose from; 2 pipes, 3 pipes, air and water-cooled along with Gas Driven systems for buildings with power limitations. When the indoor units are in the cooling mode, they act as evaporators; when they are in the heating mode, they act as condensers.

Firstly, the 2-pipe heat pump system;

This particular system is perfect for simultaneous operational hours in locations such as retail stores, cellular offices, open plan areas or any other area that require heating OR cooling exclusively. This is due to the systems’ limitation to only cool or heat spaces altogether but not do both at the same time.

Secondly, the 3-pipe heat recovery system;

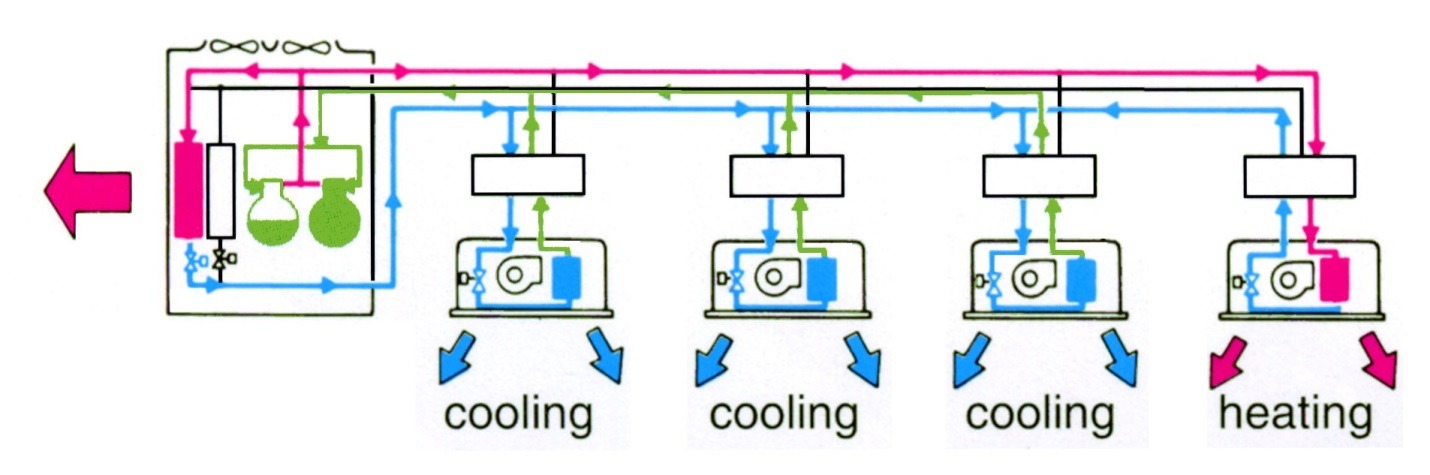

Unlike the 2-pipe HPS, the 3-pipe configuration allows simultaneous heating AND cooling between spaces and zones. Each indoor unit is branched off from the 3 pipes using a splitter which is controlled by a combination of valves.

When the indoor units are within the cooling mode, they act as evaporators; once they are within the heating mode, they act as condensers. an inside unit requiring cooling will open its suction line and liquid line valves and act as an evaporator. an inside unit requiring heating will open its hot gas and liquid line valves and can act as a condenser. Heat rejected from working space being cooled could be used to heat another space without any more energy addition. This balancing act has the potential to produce significant energy savings.

Finally, the water-cooled system;

The water-cooled system components are in fact identified as the previously mentioned systems, with one exception being that the condenser’s primary heat exchanging medium is water, with heat conduction through flat plates to increase the water’s temperature. Such a system is used when vertical space used for risers for an air-cooled refrigeration system is unavailable and space restrictions apply.

The system is noticeably quieter and vastly improves space usage. Moreover, the water loop used is easily routed to its dry cooler or its cooling tower.

Variable Refrigerant Volume (VRV)

While the differences between VRF and VRV systems can be minimal and might go unnoticed, both systems have a degree of exclusiveness to be considered.

VRV systems are technologically more sophisticated in its smart control of the refrigerant specific volumetric expansion and the resulting cooling effect. This is done to precisely tailor the building or zone’s requirements of cooling or heating to its specific needs to minimize the operational cost (electricity, maintenance, etc.) of the HVAC system. In fact, VRV is the most energy-efficient cooling solution available if executed and installed perfectly.

The system has multiple controllers that monitor a range of parameters and use a lot of sensors to optimize power usage. This includes but not limited to personal movement in and out of zones, patterns of heating or cooling needs, motion sensors, planned meetings at a zone in a specific time and so on. Several zones might even be independently shutoff to halt power draw.

The mechanism achieves more sustainability in the long run, as end-users save on energy costs while reducing their system’s carbon emissions.

Each individual indoor unit determines the capacity it needs supporting the present indoor temperature and requested temperature from the remote.

The overall demand for all indoor units will determine how the outdoor unit adjusts the refrigerant volume and temperature accordingly. By only supplying the cooling or heating that’s needed, the compressor continues to save lots of an outsized amount of energy during VRV operation.

Additional information about both variable refrigerant systems include;

- Limited power availability or loss can be overcome via use of a gas driven engine; this ensures normal operations of the refrigeration system at any time. This is a complementary system to any HVAC system in case of an emergency.

- Both systems have a modular design approach allowing easily upgradeable units and components at any time. This is done without downtimes of the system except when a major repair is needed (such as replacement of the main compressor unit).